SUSTAINABILITY

Conspiracy Chocolate was begun by two humans living on planet Earth during a time where humans are concerned about our home. This planet’s habitability to us humans and fellow animals is everybody’s concern. Still, we feel that as a business so close to nature, this topic touches close to home and we carry a further responsibility, not only to build our company’s operations sustainably but also to lead by example.

Sustainability in food supply chain is a challenge because it is often weighed not only against profit, but also against food safety on the way to and in your favourite shop and in your home. The good news is that good people around the world are working on solutions to these issues, and therefore every day we get closer to meeting all of our sustainability goals.

In this page we will track our goals, our progress, and our challenges in making and delivering chocolate safely to both your and our planet’s health.

There are some challenges we have not yet identified a solution to which meets all of the criteria for safe and affordable chocolate products. While we do our best researching and implementing solutions, we are open to hearing yours. Every one of our goals is open to discussion. Whether you are a sustainability professional or just a smart human, we are interested to hear your ideas to meet the goals we are still working on. Please do get in contact if you would like to help, even if it’s only half an idea.

For those looking for our clear-cut commitment, you can find our sustainability statement here.

Goal: Zero organic waste in the Chocolate Lab

Food production kitchens often have huge amounts of waste. Restaurants, caterers, and food factories create problematic amounts of food waste on a daily basis. Conspiracy’s Lab creates everything from scratch, this means we have a lot of fruit, vegetables, spices and herbs coming in fresh, daily. Some of the byproducts of processing these are organic and can turn into food with enough creativity and culinary skill. A chocolate production operation also makes a lot of (seemingly) unusable scraps of chocolate, especially in fancy chocolatier work.

Solution

Circular production: Our recipes take each other’s byproducts and utilise them. Ingredients that do not have room in any other recipe go into our R&D’s “Experimental Ingredients” box. Our chefs have to begin every R&D process by utilising these ingredients before looking for new ones.

Companion kitchens: Byproducts which fail to enter either production or R&D, and don’t end up in our team’s family lunch, get shared with our creative friends in other culinary practices for their needs.

Upcycling: Every last scrap of chocolate from our chocolatier work gets collected and saved. These get bagged and sold in food upcycling platforms Chomp and Phenix.

Composting: Lastly, any ingredient that hasn’t been used by the above practices or already went through a second/third usage and still exists without remaining flavour/texture/nutrition ends up in our friends’ local farms’ composts.

The last of these solutions to implement is composting. We began composting our food waste in December 2021.

When:

Goal: Packaging

Packaging is required to keep our products safe from the outside environment as moisture can ruin chocolate (and we are in humid Hong Kong after all…), to introduce our brand and message, and to meet sustainability requirements.

Solution: Wood pulp cellulose & paper

This has been one of the biggest challenges for us. We have a range of products in different shapes. Most of them are in biodegradable and recyclable packaging made of paper and tin, and some are not.

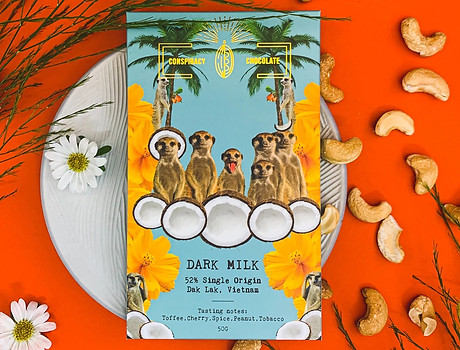

Our main product, the chocolate bars are packaged in a paper envelope lined with plastic. A chocolate bar requires an air-tight, food-safe material that blocks light and does not dramatically increase the bar’s price to the customer.

After much research and our own trials we found that most products which claim compostability do not actually break down.

We are in progress designing a new set of packaging which uses compostable vegetable-based plastic as an internal liner, keeping our chocolate safe from moisture, and an external paper casing that protects it from light.

More information about the new packaging here. To see the sustainbility certificate for the material see here and the specification of the material here.

When:

The new packaging launched in July 2022. As of Nov '22 all our products are in 100% home-compostable packaging

Goal: Minimising carbon footprint in global shipping

South America and Africa have been codified as the world’s cacao supply, famous for ancient genetics and traditional processing. The chocolate making industry is rooted in these origins, it's terroir celebrated globally. When we began our cacao education, every expert recommended focusing on them. We started tasting samples and fell in love with Belize, Dominican republic and Peruvian cacao farms’ terroirs.

.jpg)

Solution: Sourcing in the neighbourhood

Asia’s ability to learn quickly and efficiently is exemplified in cacao cultivation and fermentation, and this is still a hidden secret.

In Conspiracy’s early days we were highly uncomfortable with the carbon footprint of shipping anything from across the globe. Unaware of this secret, we thought we were taking a chance sourcing in the neighbourhood. We started roasting and grinding cacao samples from the Philippines, Indonesia, Malaysia, Vietnam, Thailand, and Taiwan. On a personal trip to Vietnam, Celine enjoyed some cacao from Tien Giang and Dak Lak and brought samples home. We enjoyed both. At the time we were close to making the call on cacao from Davao, Philippines, and Dak Lak shook our confidence. We took a trip down Vietnam looking at every cacao farm and chocolate factory that will let us in, and walking around the farm in Dak Lak, seeing their trees and fermentation operation, we were convinced this is the right partners for us.

While the world still looks at SA and Africa as the prime source of cacao, Asia is making progress. Taiwanese cacao is winning global competitions and Vietnamese cacao is celebrated by chocolate makers from Hong Kong to Canada.

When:

December 2018

Goal: Farmer’s fair pay

It is no secret that the cacao industry is full of exploitation. In a system prone to this issue, it is usually the party with least bargaining power who gets the short end of the stick.

As a result of conditions set by colonial powers over their annexed cacao growing territories (hot, humid countries capable of growing this plant), and systemised during the industrial revolution, this party ended up being the farmers, and local co-operatives.

Cacao farmers, in particular those in West Africa, are exposed to market forces that lead to their being underpaid for their work, below acceptable living wages. These large-scale underpaid operations lead to huge issues on the ground including unfair wages and working conditions, often slavery and child labour. These issues are intertwined with their local economies’ challenges and are abused by large-scale chocolate manufacturers who enjoy higher margins and immense volumes, gathering buying power.

There have been attempts at resolving this including the Fair Trade certificate, but so far none of them have proven effective enough to end this exploitation and it’s cascading, radiating effects.

Solution: Direct trade and farmer-controlled pricing

The farm who supplies Conspiracy Chocolate runs their own business independently, determining their own pricing. This also allows them to focus on ambition in quality and a sustainable business model of healthy margins and fair wages. The price we pay this farmer for their fermented, dried cacao beans is 2.4x that of the Fair Trade certificate’s designated price for the same product.

This model works not because customers full of kindness would like to hand over more money for the same product, but because this model enables the farmer to hire scientists and other experts and create a high quality, competitive product worthy of a higher price.

They are therefore also capable of becoming a brand like in wine’s terroir, allowing demand to form as their uniqueness is not interchangeable with another origin’s genetics or processing.

When we placed our first order with this farm, it was their first ever export out of Vietnam, in late 2018. Since then their terroir’s brand is globally known and their pricing widely accepted among bean-to-bar chocolate makers - not out of kindness but out of appreciation of a high quality product that is simply worth this price. This issue is wide (globally) and deep (locally). It is complex at both levels. At Conspiracy Chocolate we have the “luxury” of small scale artisan production. While solving this issue at our size is currently manageable, we will face another version of it as we grow. Our plan for dealing with it at that scale once we reach there is limiting batch production volumes to the capacity of high quality farms and maintaining pricing as such that allows our farmers to maintain the healthy businesses they run. By then, we will work with multiple origins and offer the chocolate’s volume that can be made of what is available.

When:

September 2018

Goal: Zero inorganic waste in the chocolate lab

Some of our raw ingredients come into the Lab in plastic packaging for food safety and transportation reasons.

.jpeg)

Solution: Reliable, affordable recycling solution

…and reduction of packaging from suppliers. These are our identified potential solutions. We are working on implementing them.

We have set June 2023 as a target for reaching this goal by identifying the correct recycling partners and negotiating reduced packaging from suppliers.

When:

Goal: Minimising carbon footprint in local shipping

Our deliveries of products from the Chocolate Lab to homes, restaurants and shops are carried by local logistics solutions, leaving a carbon footprint that we believe can be reduced.

Solution: Consolidating deliveries

Our website orders that do not include glassware are carried out by SF express who consolidate deliveries by region. Our orders to restaurants and shops are carried by couriers. The majority of them use public transportation. Still, this is an area where we would like to improve.